Motorized Collimators

Type KM - Motorized Collimators

Type KM - Motorized Collimators

Product description

The collimators are designed for active alignment of cameras for the automotive industry. As standard, the collimators are equipped with a reticle for MTF measurement (transparent crosshair on dark background, slit width 10 µm). There are 4 different focal lengths to choose from. These allow an ideal adaptation of the achievable image distances to the optics to be tested.

Overview

Motorized Collimators

Reticle Patterns

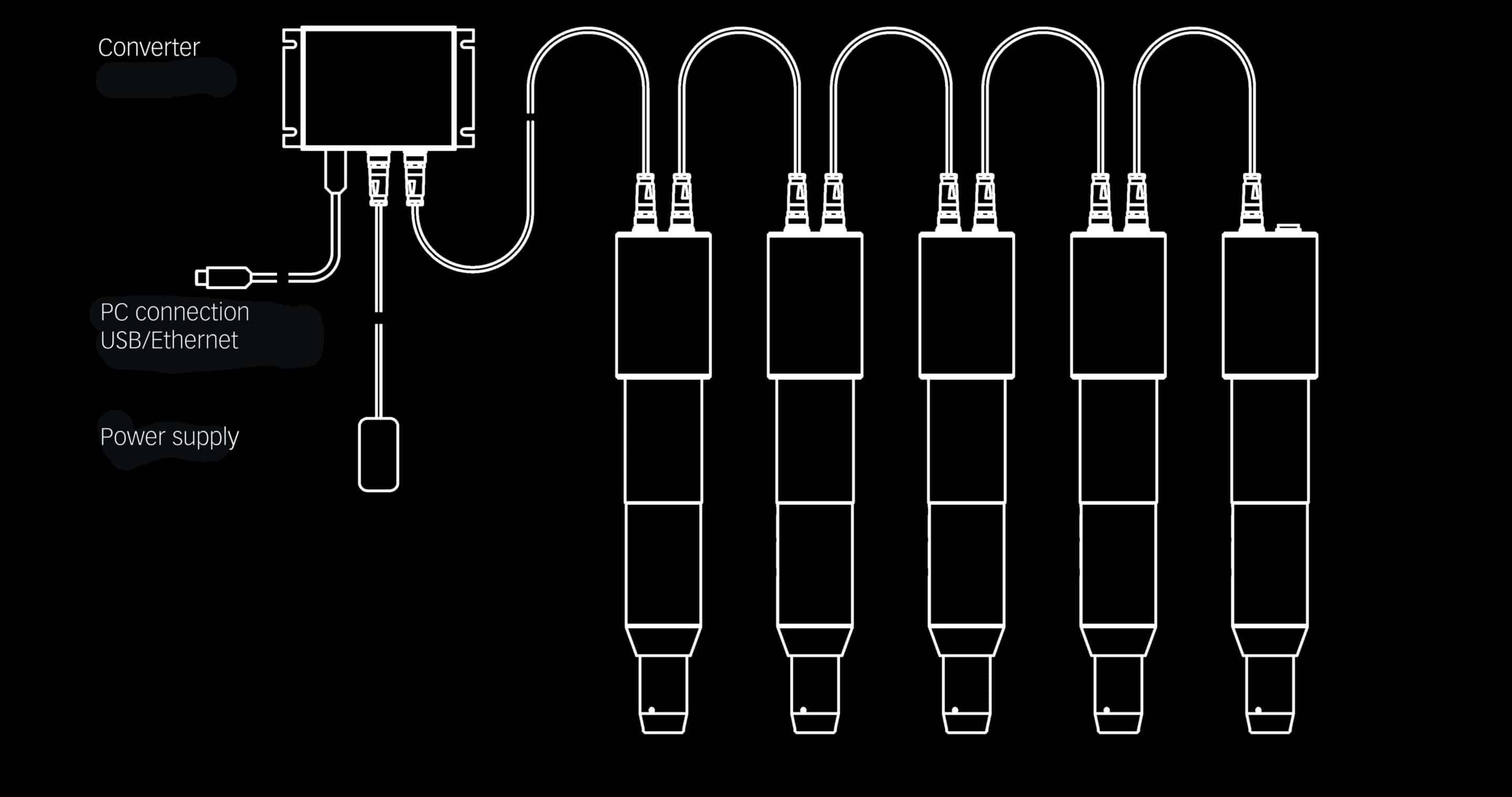

Converter

A converter is required for each collimator system. The converter-system can control multiple collimators. The scope of delivery of the converter includes the power supply and the connection cable to the PC or control cabinet (Ethernet/USB 2.0).

Hardware and Software Integration

The collimator contains the illumination unit and all the control and evaluation electronics. Multiple collima-tors can be addressed and connected in series. The customer software communicates via USB or Ethernet with the converter box, which in turn controls the individual collimators. In addition to the ease of software implementation, the series connection allows for easy cabling and maintenance of the collimators. When replacing a single collimator, only the addressing needs to be transferred. This means that replacement can be carried out in a very short time and with very little effort. Each collimator is supplied with a RS-485 connection cable.

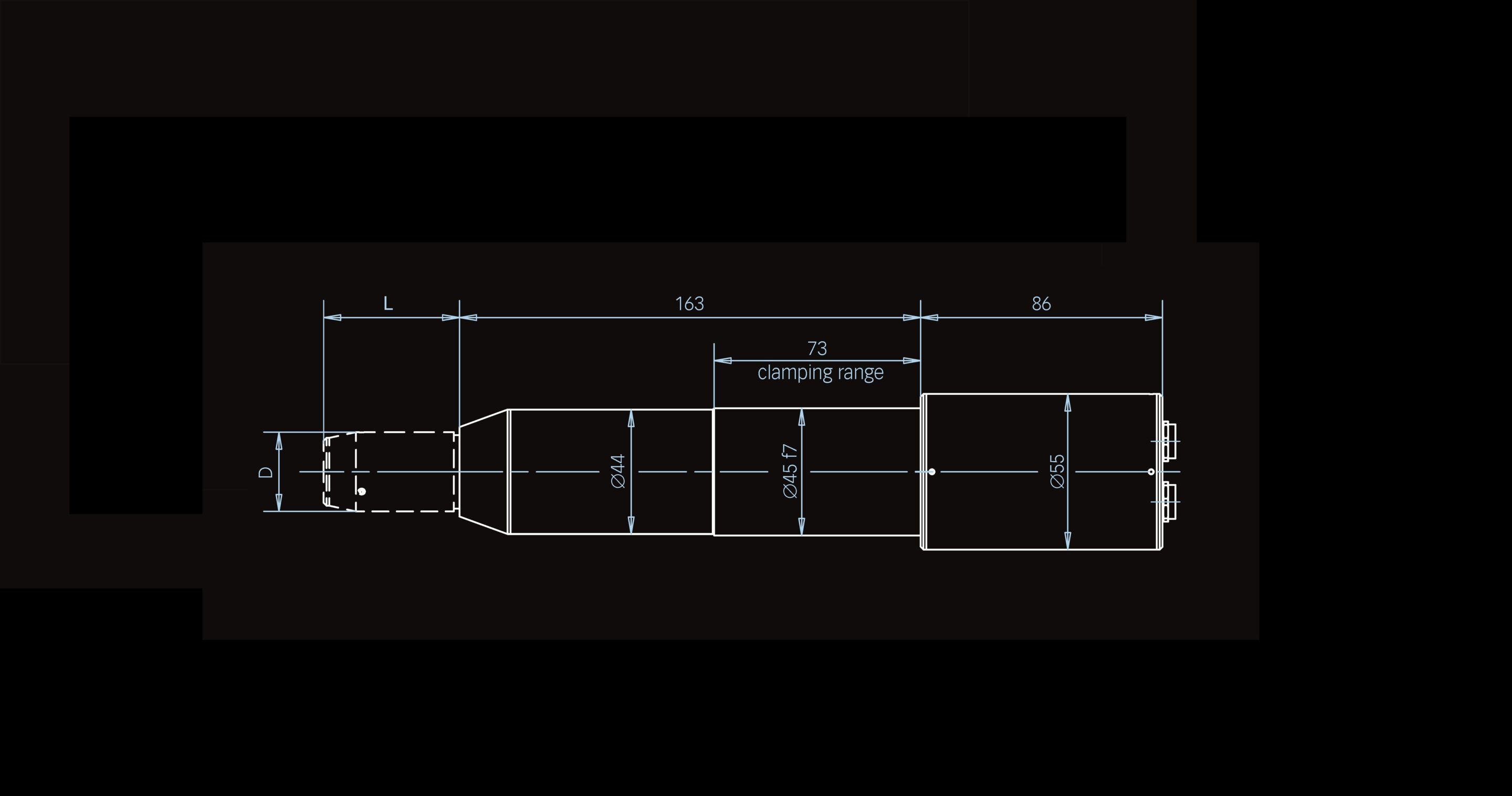

Dimensions

The clamping range and clamping diameter are the same for all variants. Even if the collimators are retrofitted with different objective tubes, users can continue to use their existing mechanical mounts. For dimensions (Length and Diameter) of objective tubes, please see technical data below.