Electronic Autocollimators

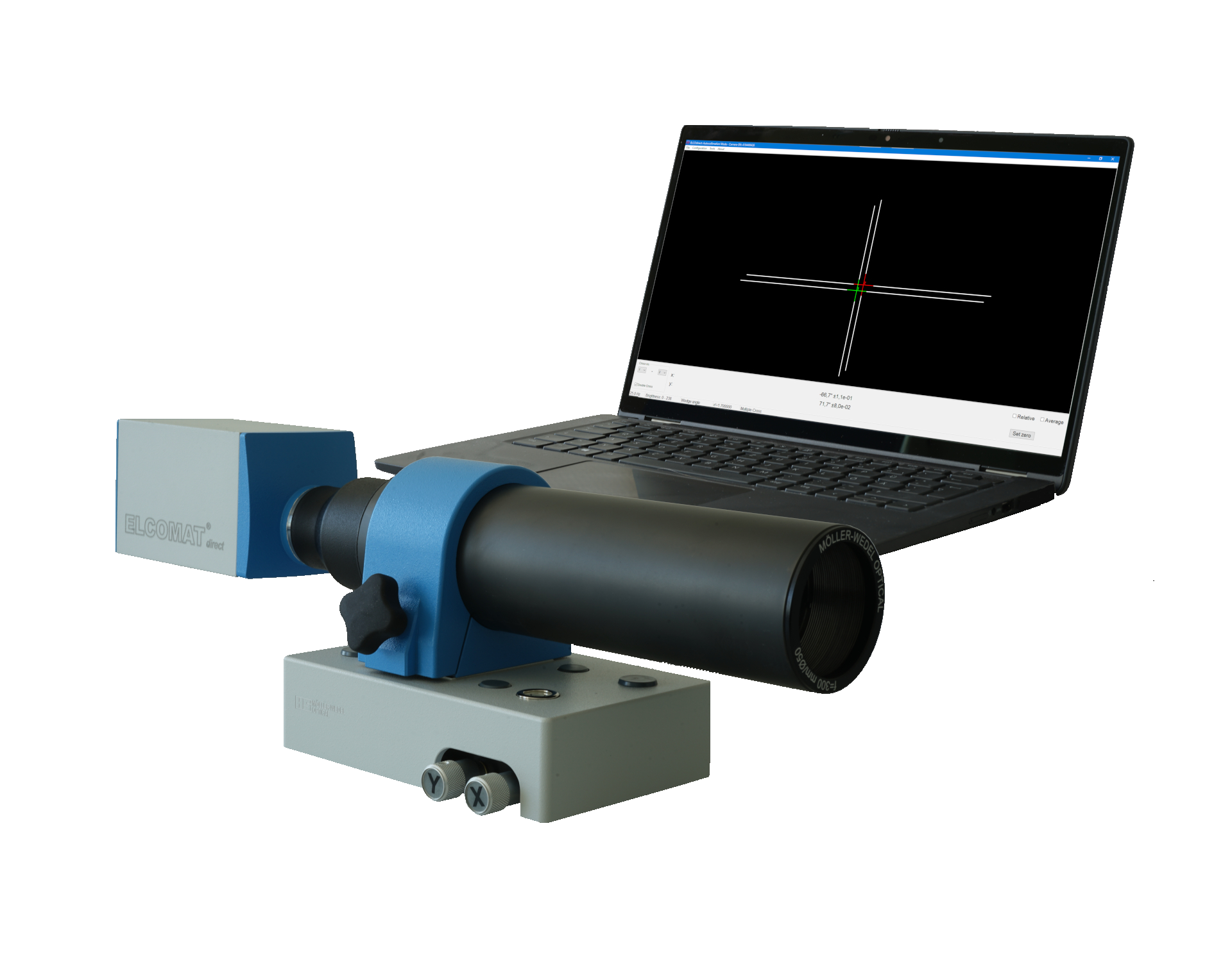

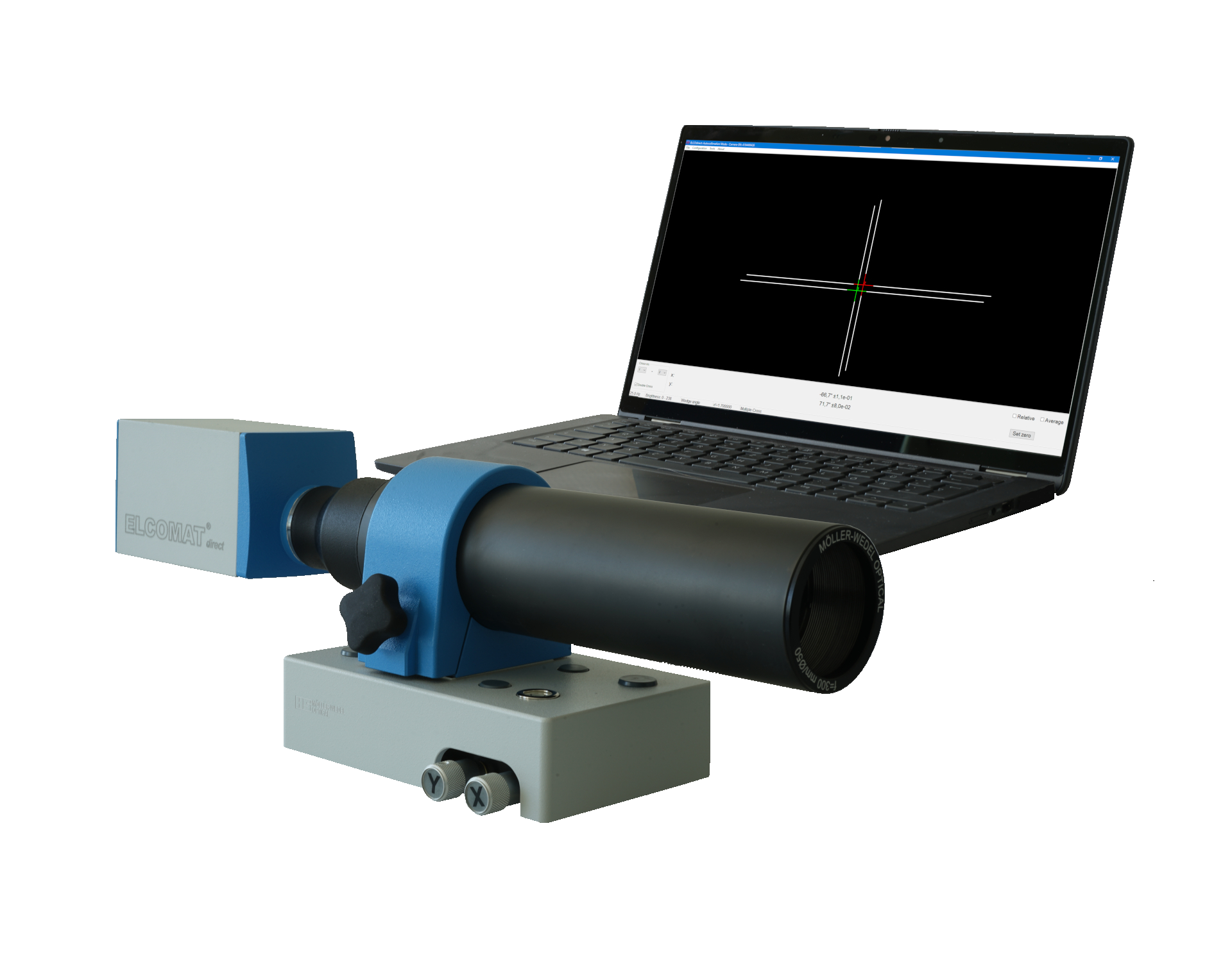

ELCOMAT® direct N Product Line

ELCOMAT® direct N Product Line

Product description

Each ELCOMAT® direct N consists of the autocollimation sensor and the software ELCOdirect. ELCOdirect can be used with Microsoft® Windows and a current PC, laptop or notebook. The autocollimation sensor is connected to the computer via the USB interface. A Microsoft® Windows Dynamic Link Library (DLL), autocollimation function, is included with the software ELCOdirect.

ELCOMAT DIRECT PRODUCT LINE

Introduction

- measurement of small angles

- high precision angle adjustment and calibration

- assembly automation

- wedge and prism angle measurement

- angular position monitoring

INTRODUCTION

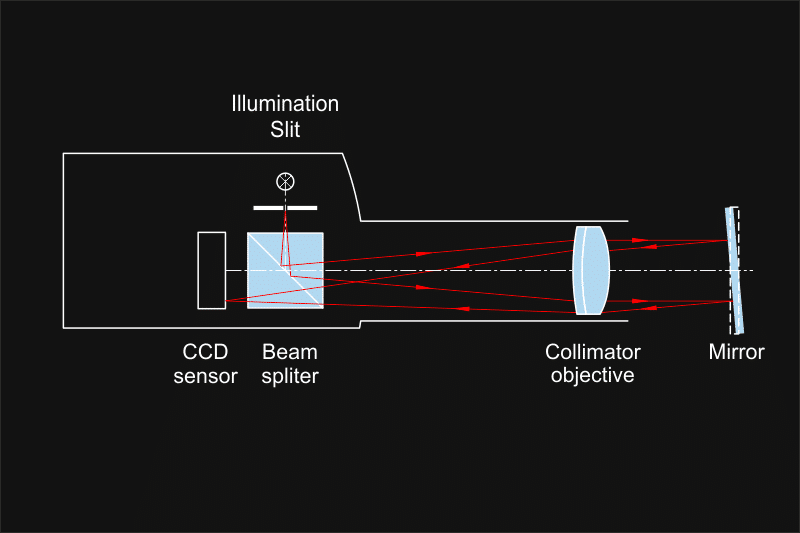

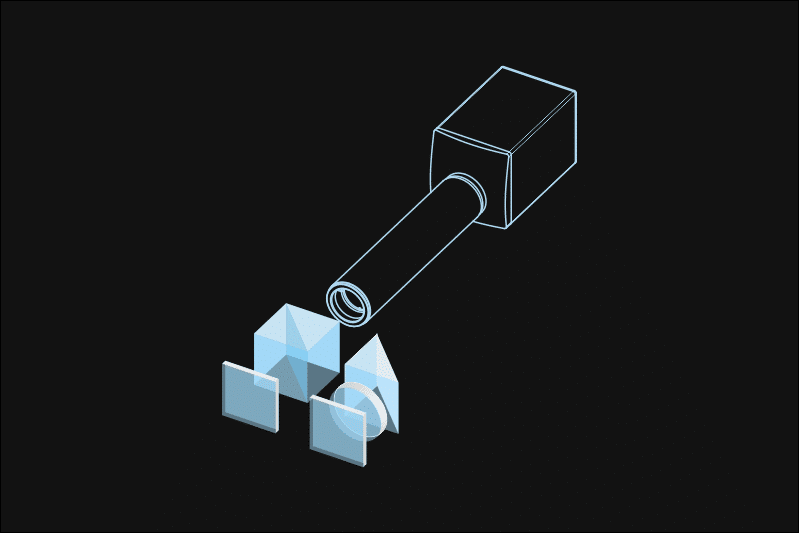

Measuring Principle

INTRODUCTION

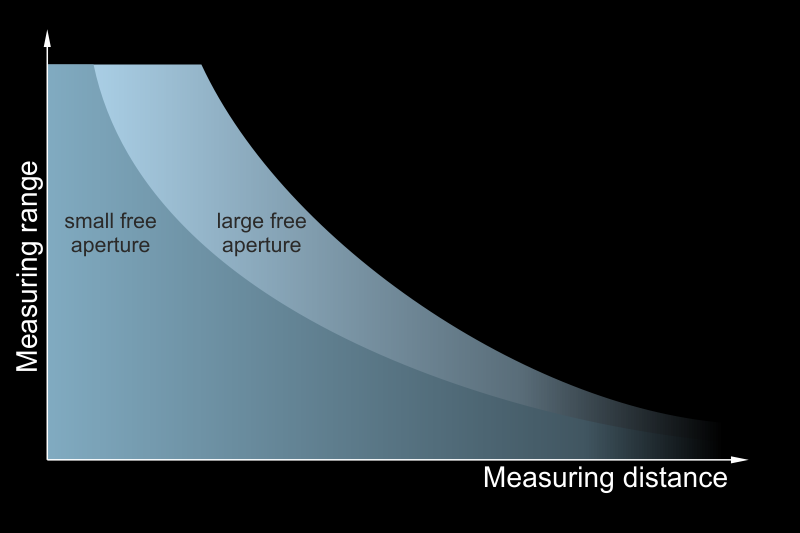

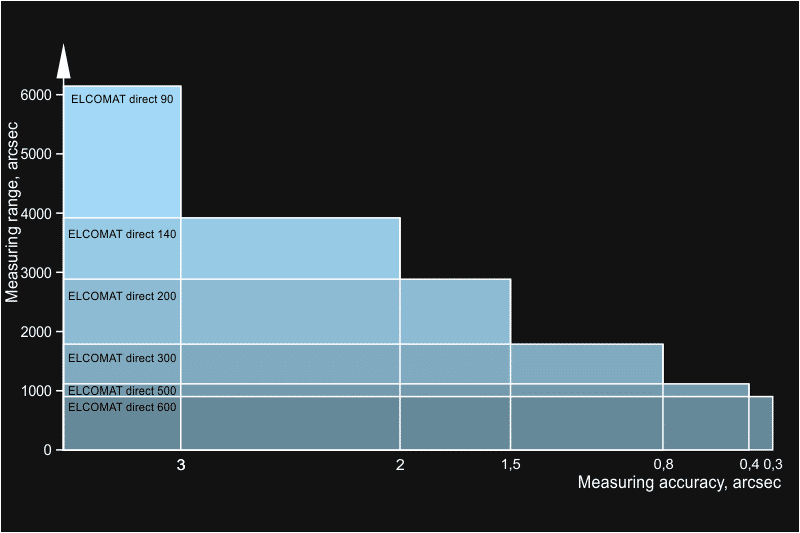

Measuring Range and Distance

INTRODUCTION

Selection Criteria

ELCOMAT DIRECT N PRODUCT LINE

Features

- fast and easy measurement of small angles with high accuracy

- computer-based evalution

- connection to computer via USB 2.0 interface or higher

- simple operation

- cost-effective measuring system

- easy integration into automated processes

ELCOMAT DIRECT SERIES

Typical Applications

- Wedge angle measurement

- Angle measurement of 90°-prisms

- Adjustment of optical components

- Parallelism of two surfaces

- Position uncertainty

- Wooble

- Centering

TYPICAL APPLICATIONS

Wedge Angle Measurement

TYPICAL APPLICATIONS

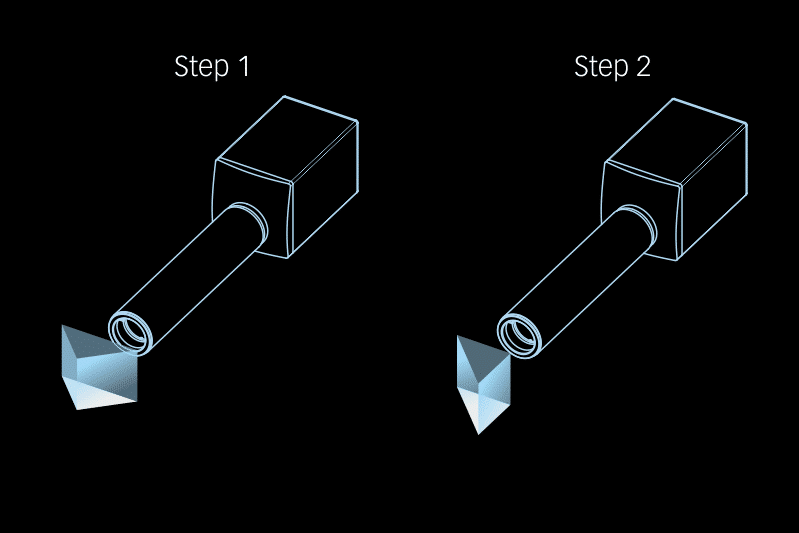

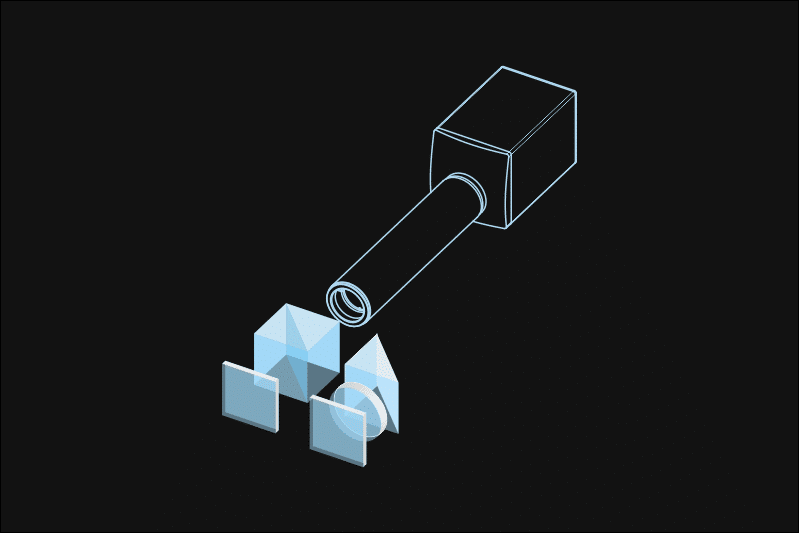

Angle Measurement of 90°-Prisms

TYPICAL APPLICATIONS

Adjustment

TYPICAL APPLICATIONS

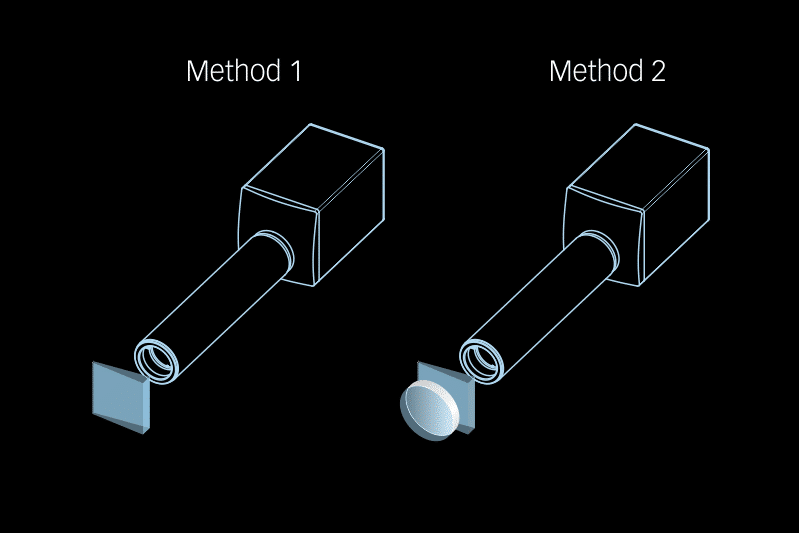

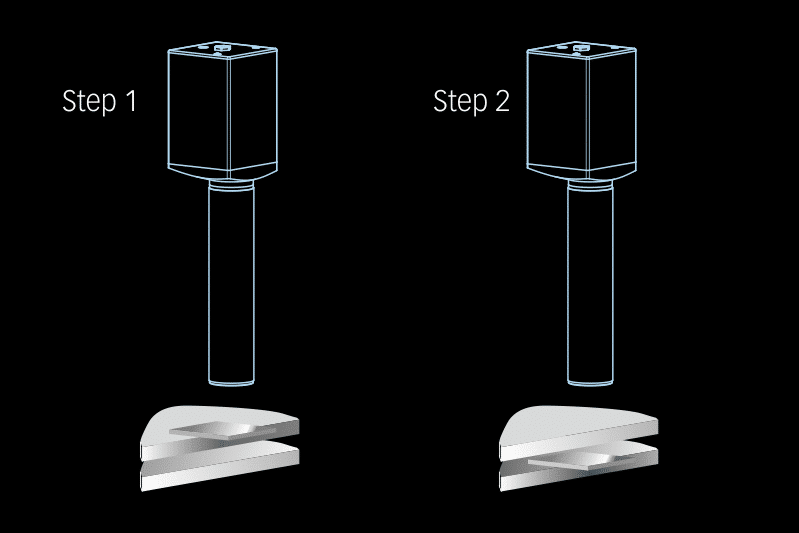

Parallelism of Two Surfaces

TYPICAL APPLICATIONS

Wobble

TYPICAL APPLICATIONS

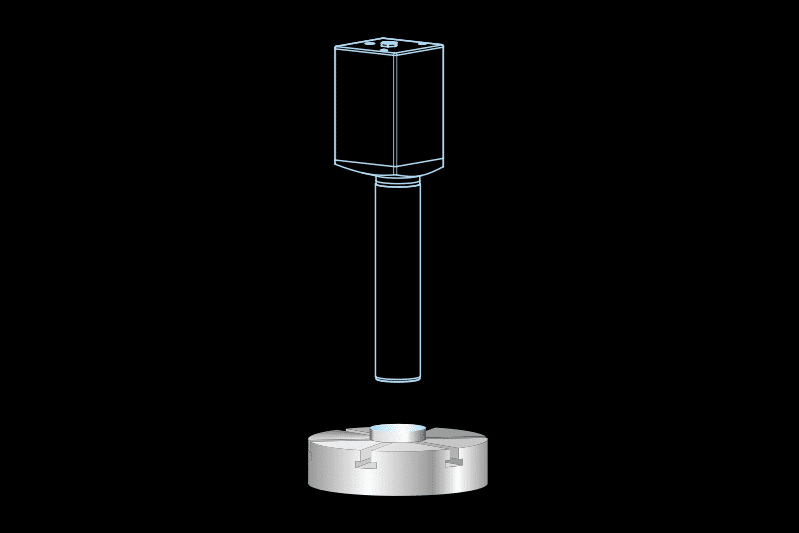

Centering

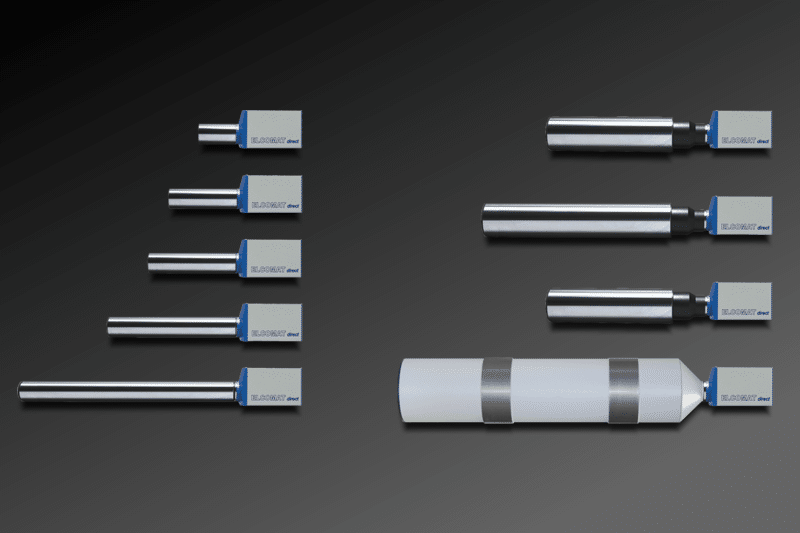

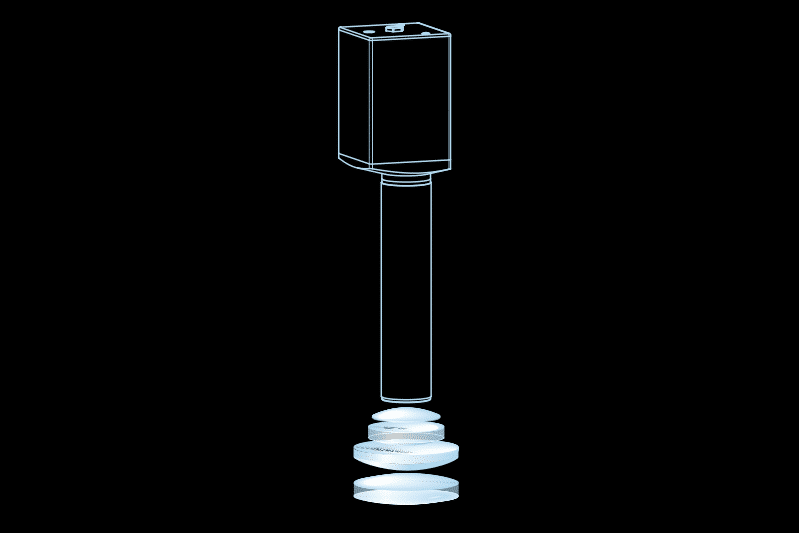

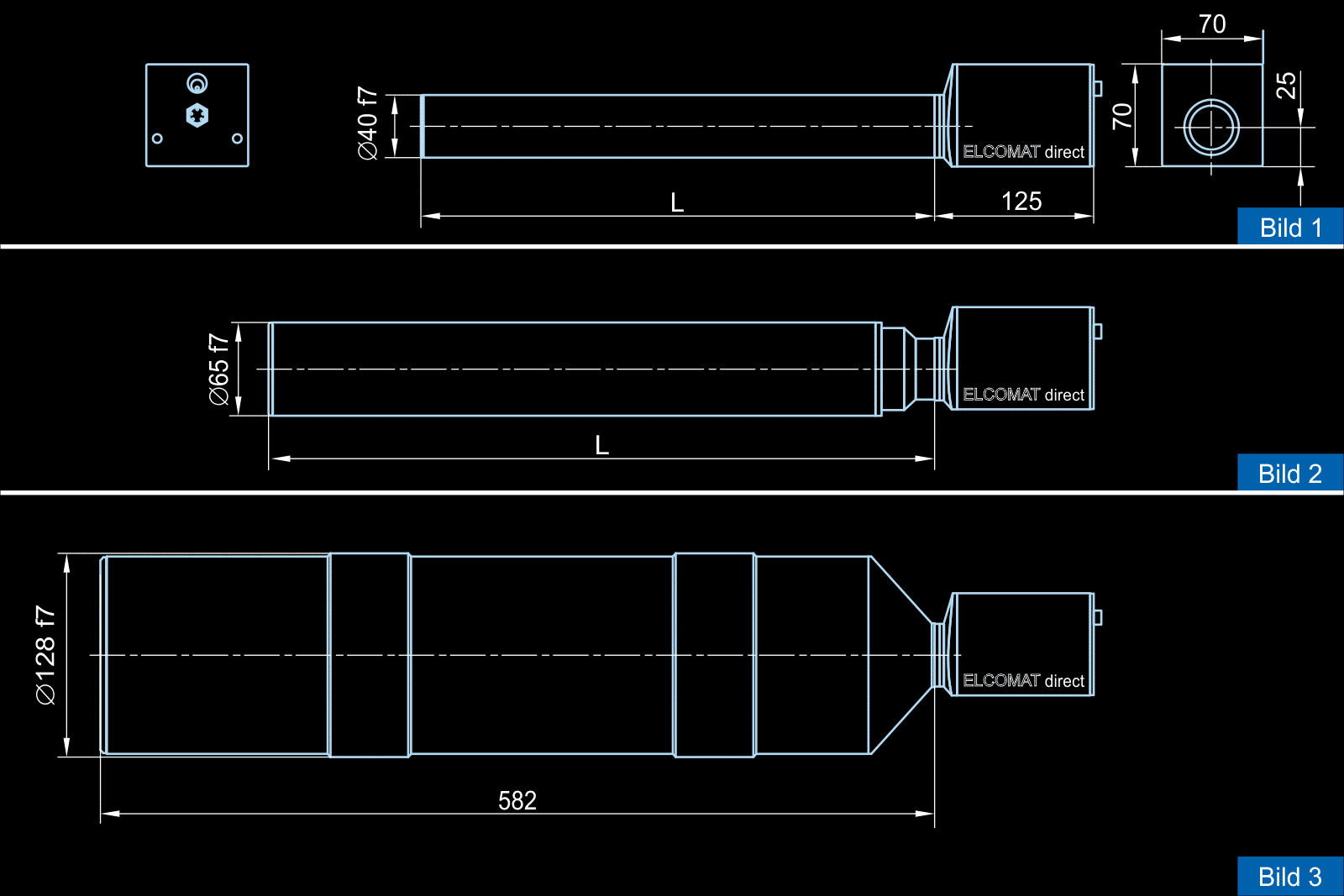

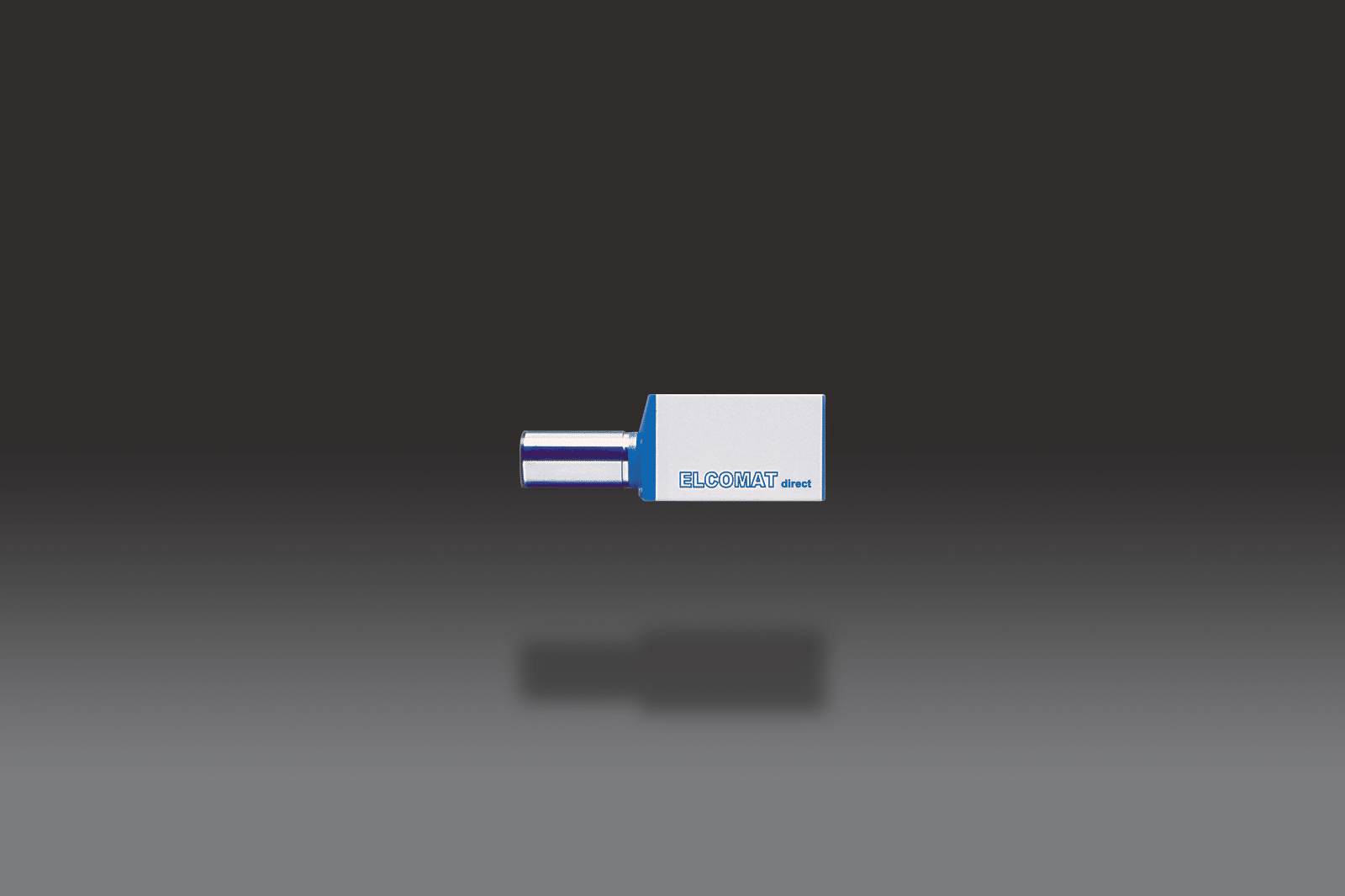

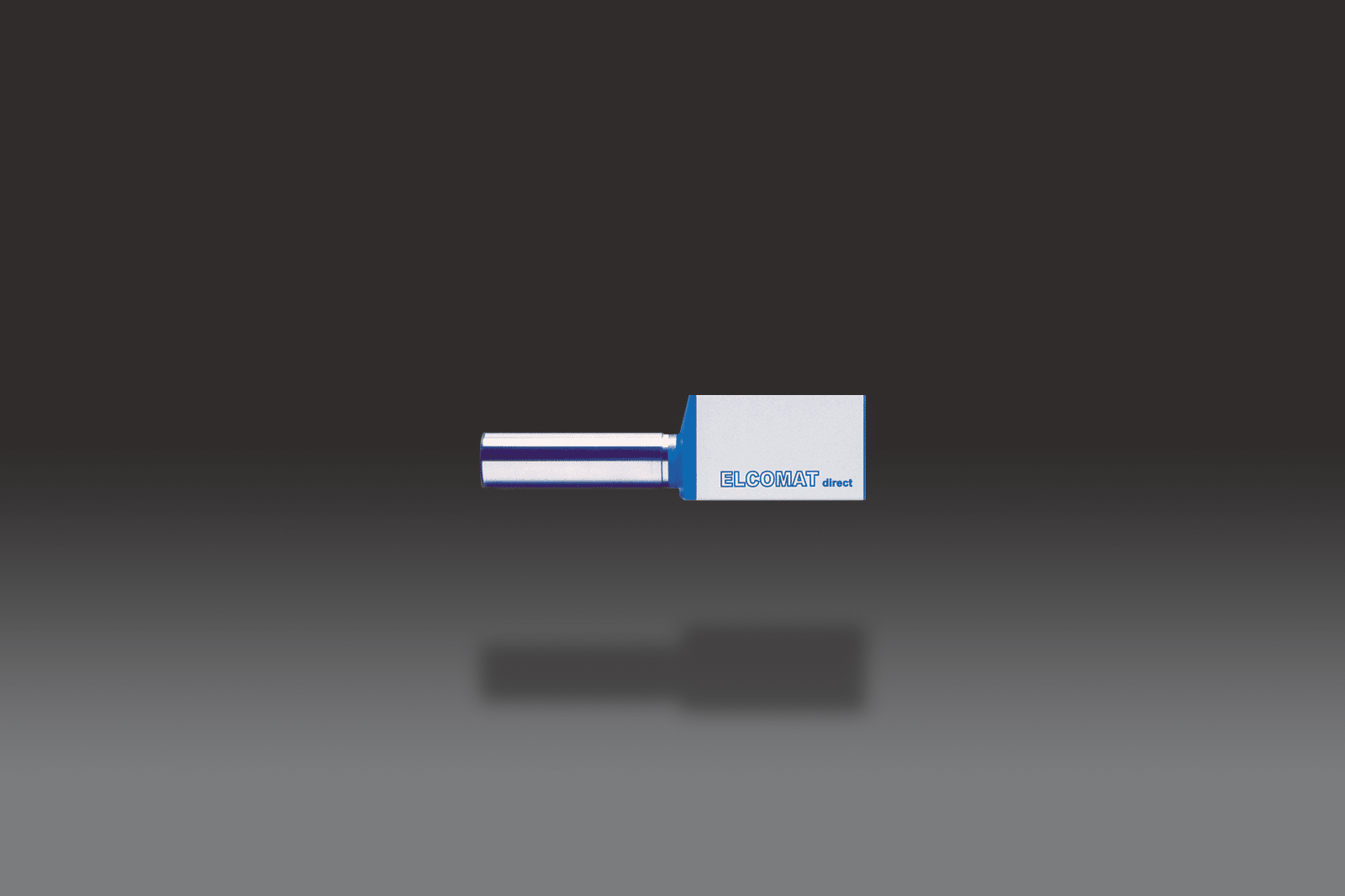

Sensor Dimensions

*Compact Design

Subject to technical changes

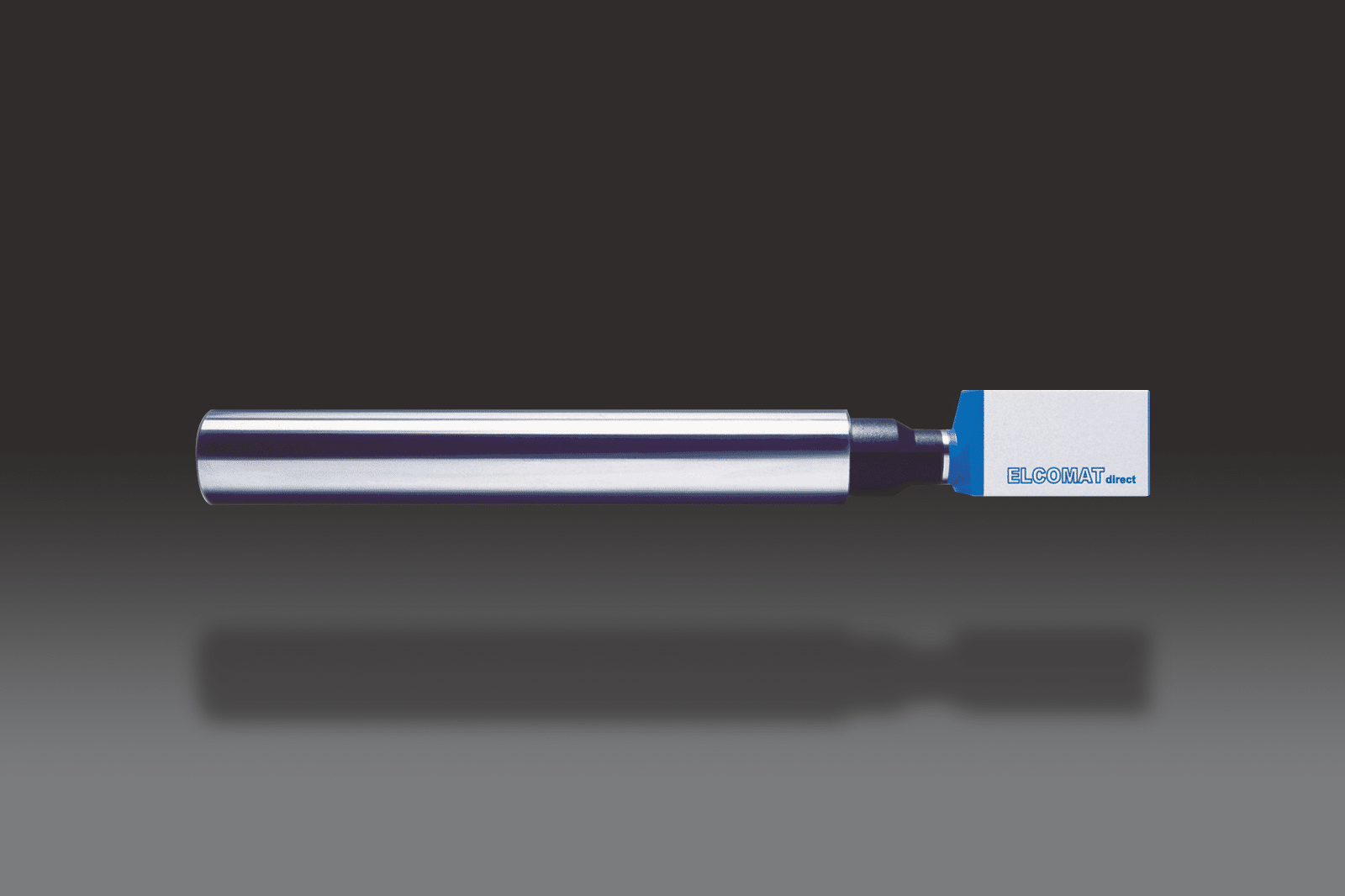

ELCOMAT direct N 90/40

* The minimum detectable angle difference is the minimum angle between two reflecting surfaces at which the ELCOdirect software can still detect two separate autocollimation images.

Subject to technical changes

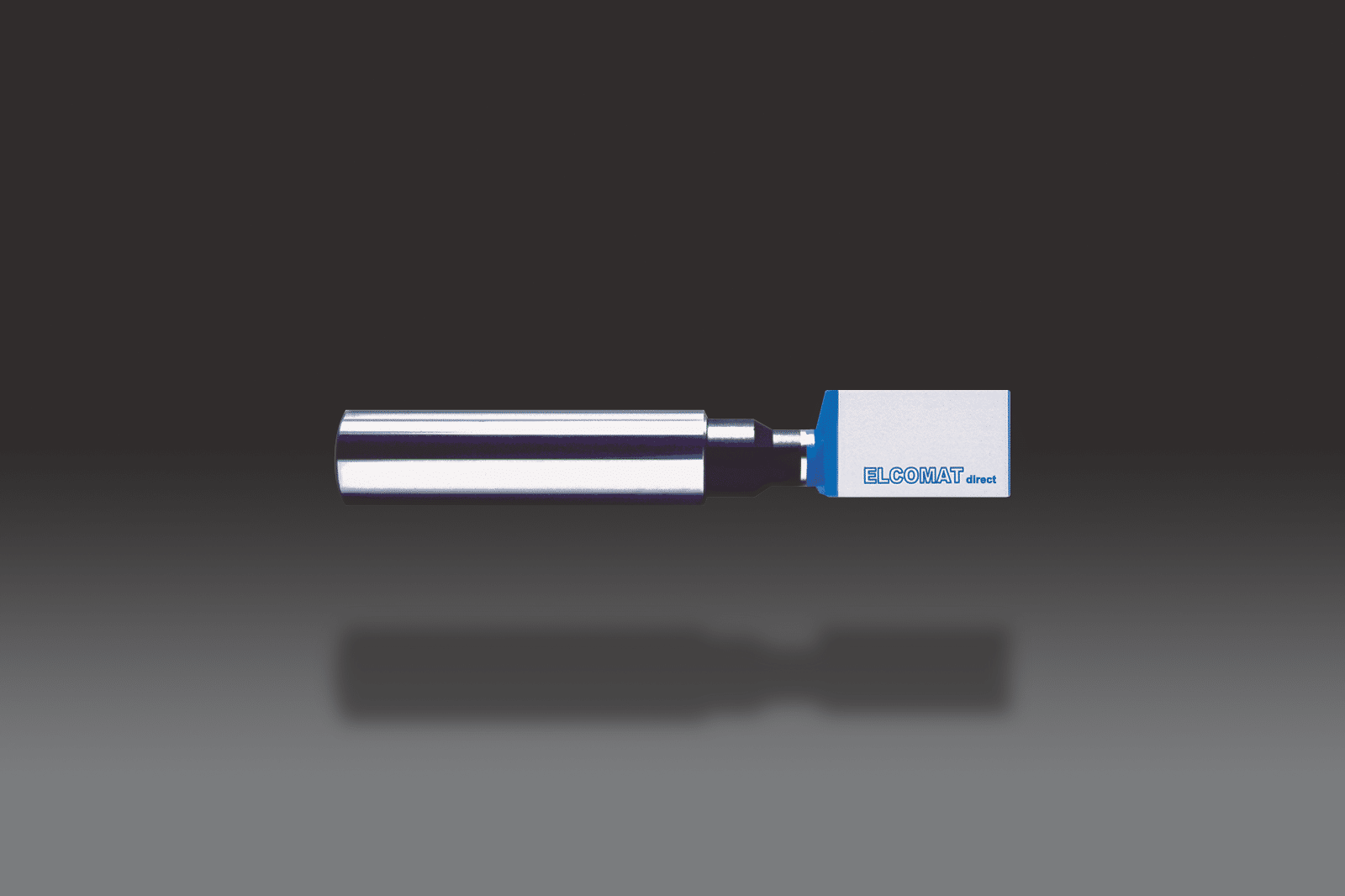

ELCOMAT direct N 140/40

* The minimum detectable angle difference is the minimum angle between two reflecting surfaces at which the ELCOdirect software can still detect two separate autocollimation images.

Subject to technical changes

ELCOMAT direct N 200/40

* The minimum detectable angle difference is the minimum angle between two reflecting surfaces at which the ELCOdirect software can still detect two separate autocollimation images.

Subject to technical changes

ELCOMAT direct N 300/40

* The minimum detectable angle difference is the minimum angle between two reflecting surfaces at which the ELCOdirect software can still detect two separate autocollimation images.

Subject to technical changes

ELCOMAT direct N 500/40

* The minimum detectable angle difference is the minimum angle between two reflecting surfaces at which the ELCOdirect software can still detect two separate autocollimation images.

Subject to technical changes

ELCOMAT direct N 300/65

* The minimum detectable angle difference is the minimum angle between two reflecting surfaces at which the ELCOdirect software can still detect two separate autocollimation images.

Subject to technical changes

ELCOMAT direct N 500/65

* The minimum detectable angle difference is the minimum angle between two reflecting surfaces at which the ELCOdirect software can still detect two separate autocollimation images.

Subject to technical changes

ELCOMAT direct N 500T/65

* The minimum detectable angle difference is the minimum angle between two reflecting surfaces at which the ELCOdirect software can still detect two separate autocollimation images.

Subject to technical changes

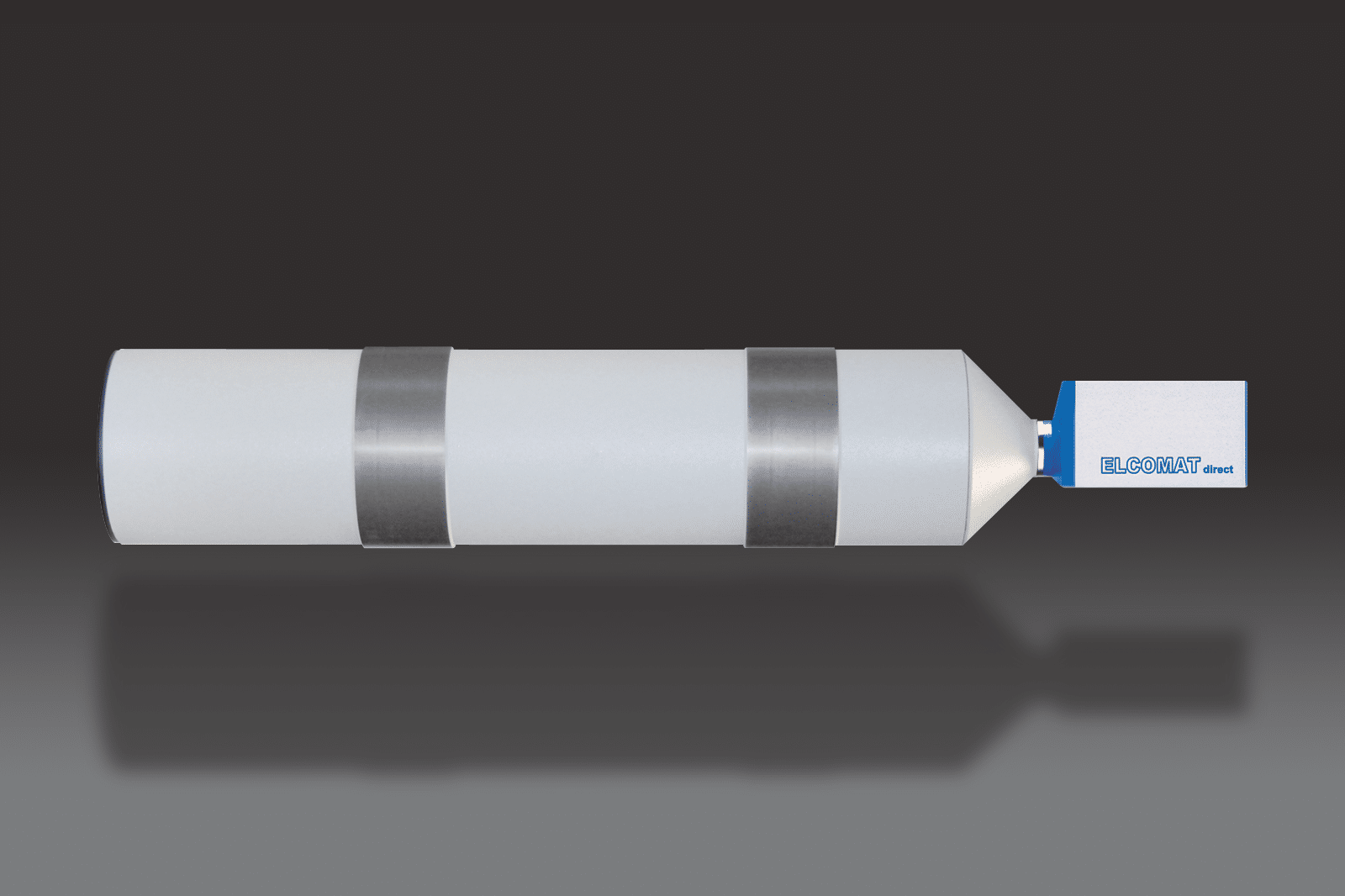

ELCOMAT direct N 600/128

* The minimum detectable angle difference is the minimum angle between two reflecting surfaces at which the ELCOdirect software can still detect two separate autocollimation images.

Subject to technical changes