Electronic autocollimators are high-precision optical angle encoders used for measuring minute angular changes and adjusting mirrors and other plano-optical components. Thus, they are ideal for angular position monitoring or adjustment of reflectors in the optical, laser and semiconductor industries. They are also widely used in mechanical engineering to measure the straightness/parallelism of machine beds, to measure the pitch and yaw movements of machine axes, and to determine the positional uncertainty of rotary and indexing tables.

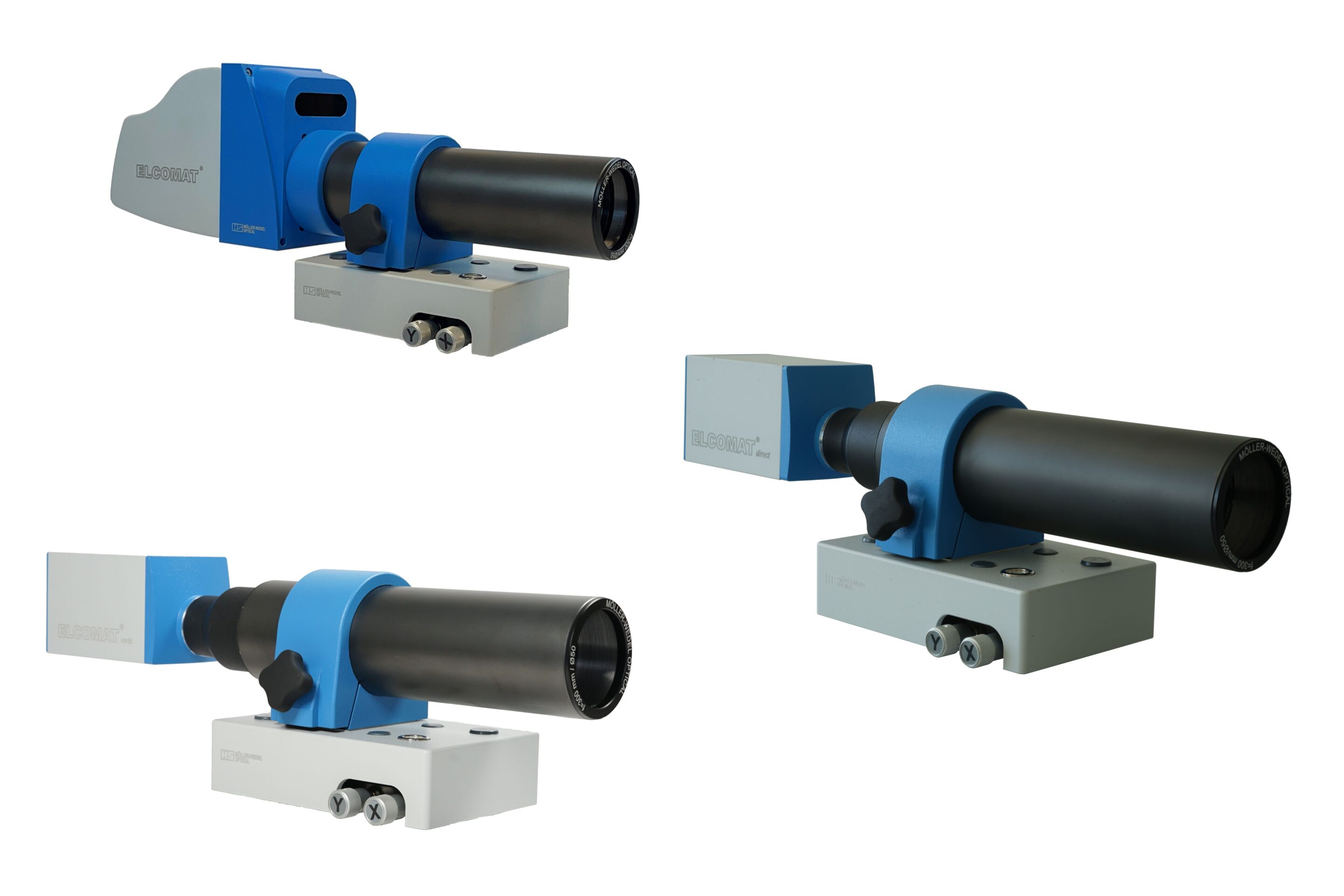

The new electronic autocollimator ELCOMAT® 5000 from MÖLLER-WEDEL OPTICAL GmbH is the consequent further development of the worldwide proven electronic autocollimator ELCOMAT® 3000. Both the hardware and the software have been newly developed. A new feature is the direct digital signal processing in the sensor head, which significantly improves the signal-to-noise ratio. Compared to the ELCOMAT® 3000, the ELCOMAT® 5000 features a 10-fold higher measuring frequency as well as a larger dynamic range (measuring range/measuring uncertainty). With the alignment aid integrated in the measuring instrument, simple, fast and precise adjustment of the autocollimator is possible, which allows safe handling of the ELCOMAT® 5000 even by personnel who are not specially trained.

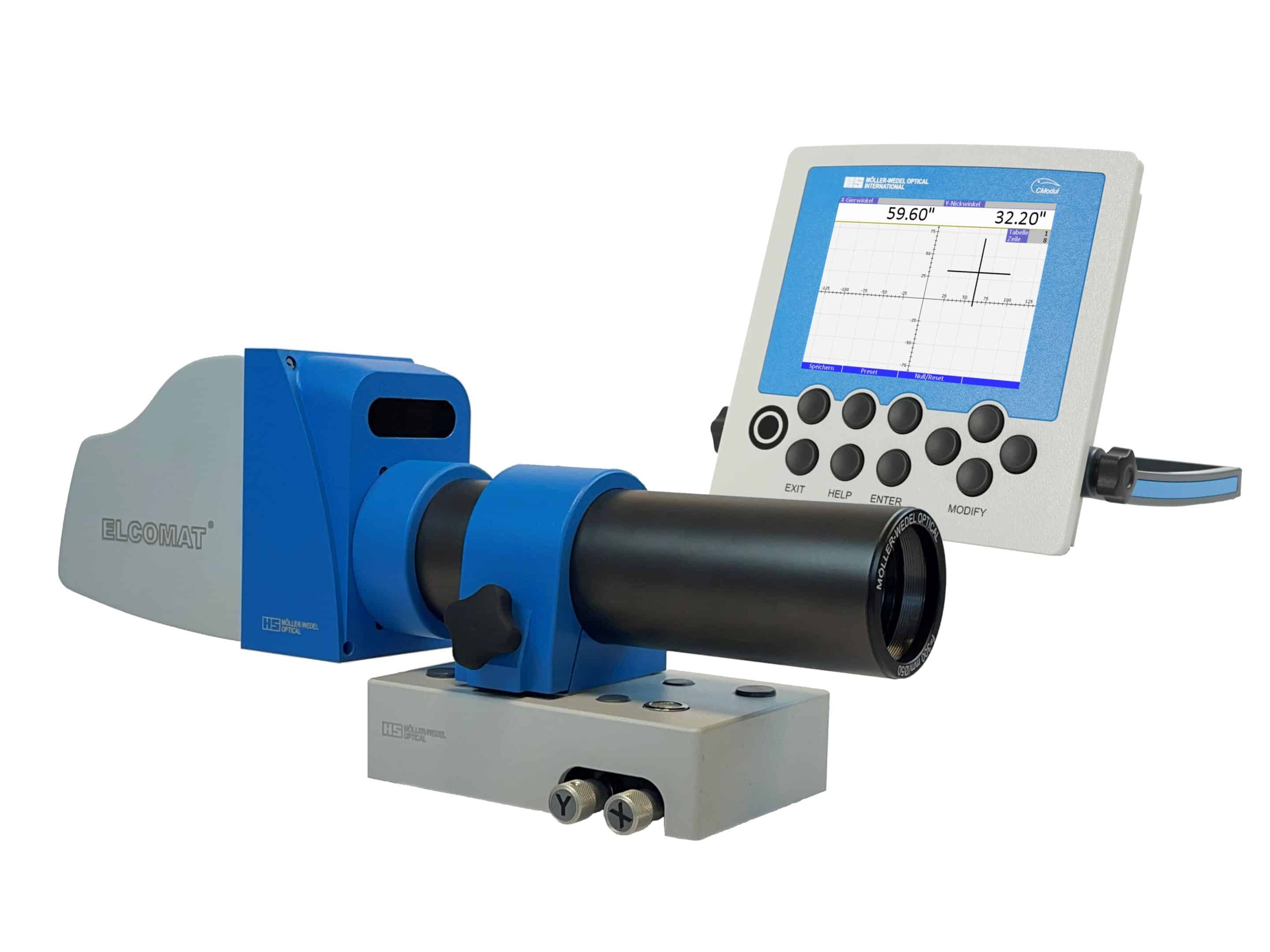

The ELCOMAT® 5000 consists of a sensor head and an intelligent display module. Thus, the autocollimator can be operated autonomously without a PC/laptop. A new feature is the software integrated in the display module, which allows the simple and fast measurement of straightness on-the-fly. Especially during the production process of guideways, this saves a considerable amount of time. MÖLLER-WEDEL OPTICAL GmbH can deliver the ELCOMAT®5000 with a calibration certificate according to DIN EN ISO/IEC 17025.

The ELCOMAT® 3000 is still at your disposal and will be maintained, repaired and calibrated by us. It can also be calibrated according to DIN EN ISO/IEC 17025.