Semi-Automatic Goniometers

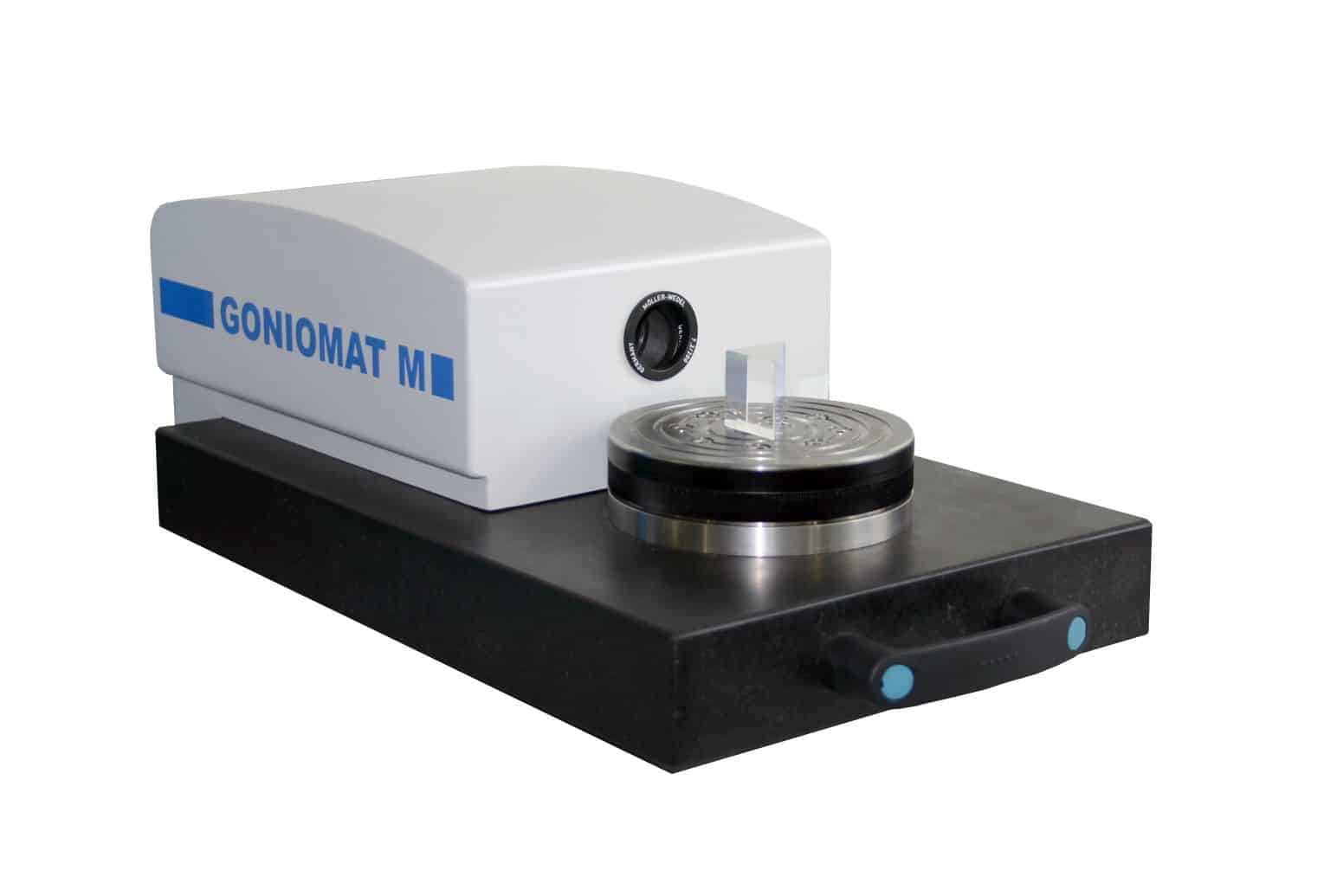

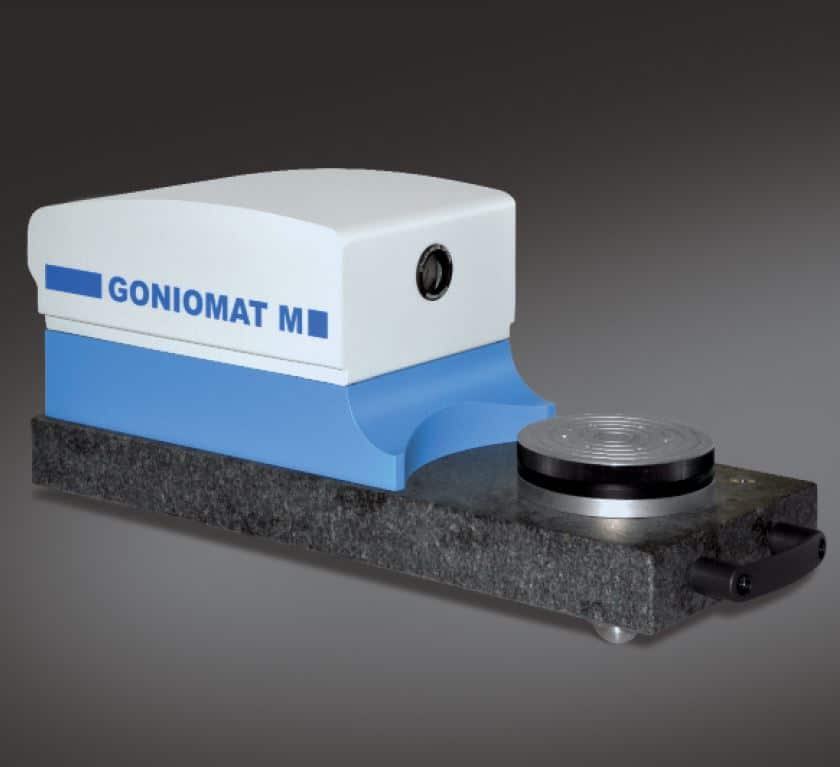

GONIOMAT M5 / M5 XL / M10

GONIOMAT M5 / M5 XL / M10

Product description

The GONIOMAT M series, with its combination of manually rotatable precision rotary table and software-supported evaluation of the angle encoder signals in relation to the autocollimation image, enables easy handling with frequently changing test specimen types and, at the same time, low measurement uncertainty. The goniometers are ideally suited for in-process production monitoring as well as incoming and outgoing inspection.

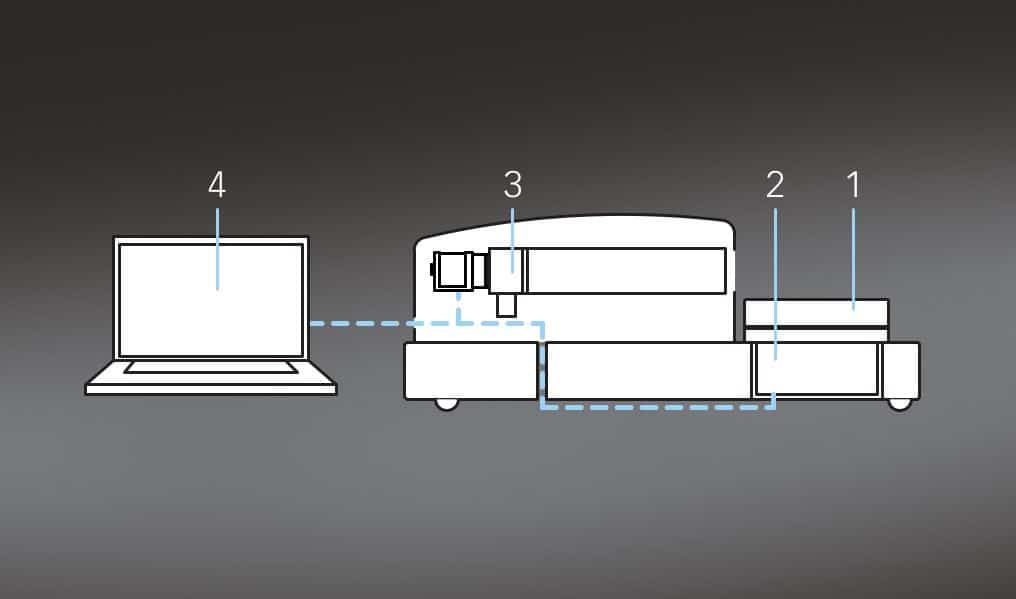

Measuring Principle

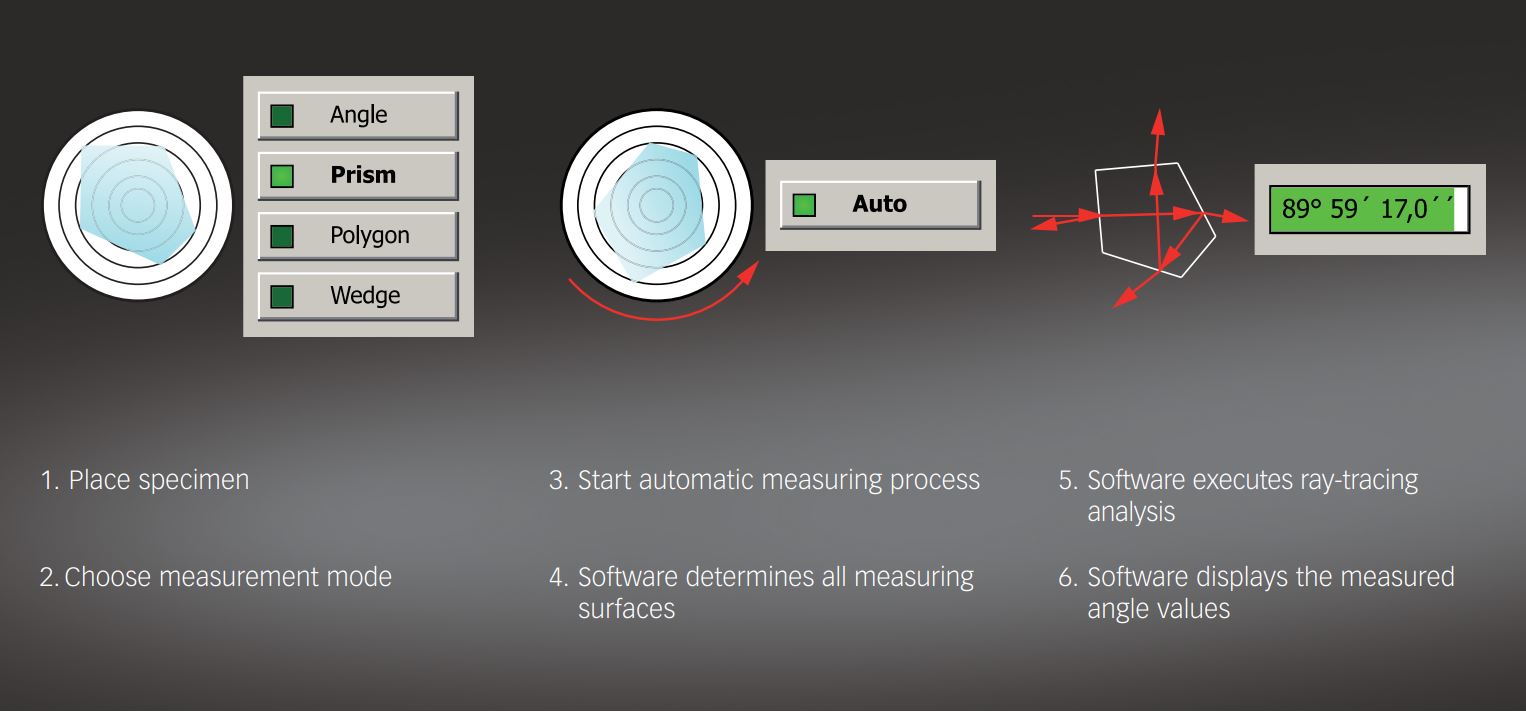

Measuring Procedure

- Operator places the test specimen on

- Align surface 1 to the autocollimator

- Select measurement mode

- Set the measured value of the first surface to zero

- Rotate table and align surface 2 to the autocollimator

- Software displays angle measurement value

Notes of ordering

The following accessories are included in the scope of delivery of the GONIOMAT M series:

- Angle Reference

- GONIOMATIK Software

- Connection Cable

- Supporting Tables H12

Technical data

GONIOMAT M5 / M10

The goniometers GONIOMAT M5 and M10 differ from each other by the used angle encoder and the resulting achievable accuracy classes. Both variants benefit from the symbiosis of modern USB camera technology with Möller-Wedel Optical standard components as well as from the innovative concept of the GONIOMATIK software.

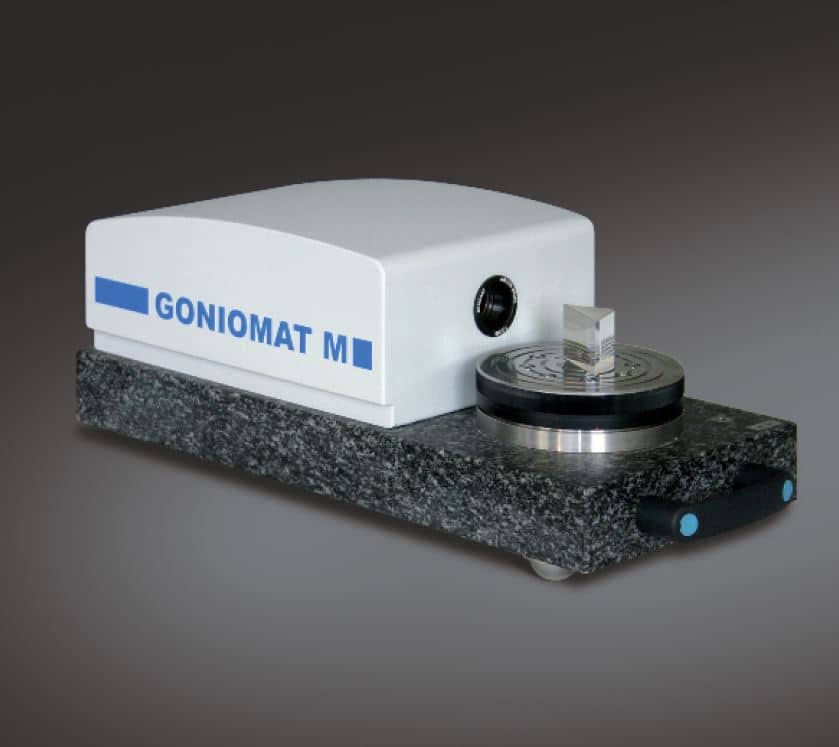

GONIOMAT M5 XL

The GONIOMAT M5 XL is particularly suitable for measuring large prisms and plano optical components up to a maximum diameter of 250 mm. The height of the optical axis, measured from the upper edge of the support table, is 90 mm. All other essential technical data correspond to those of the proven GONIOMAT M5. Special features:

- Accuracy class GONIOMAT M5 XL: 1.5 arcsec

- Height of optical axis to support table: 90 mm

- Maximum specimen diameter: 250 mm